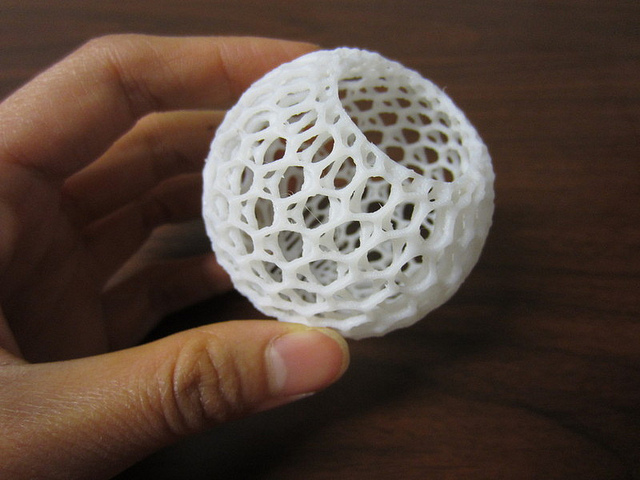

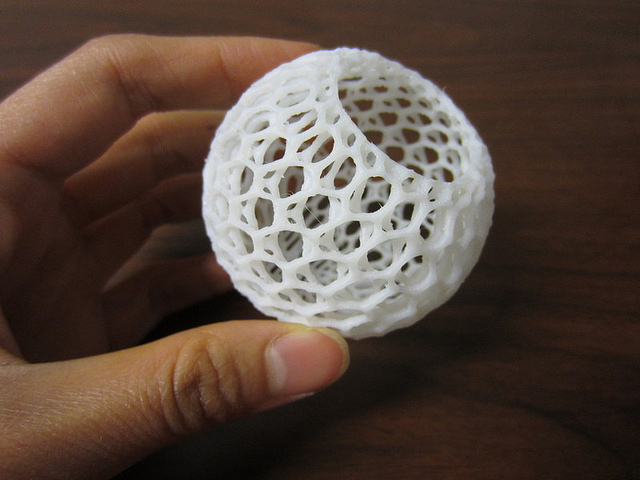

3D printing is also known as desktop fabrication or additive manufacturing; it is a prototyping process whereby a real object is created from a 3D design. 3D printing is achieved using additive processes, where an object is created by laying down successive layers of material. 3D printing is considered distinct from traditional machining techniques which mostly rely on the removal of material by methods such as cutting and drilling. The digital 3D-model is saved in STL format and then sent to a 3D printer. 3D printing makes it possible to make a part from scratch in hours; you can go from a flat screen to an exact part or object. Many different materials can be used for 3D printing, such as ABS plastic, PLA, polyamide (nylon), glass filled polyamide, stereo lithography materials (epoxy resins), silver, titanium, steel, wax, photopolymers and polycarbonate.

3D printing is usually performed by a materials printer using digital technology. Since the start of the twenty-first century there has been a large growth in the sales of these machines, and their price has dropped substantially. The first examples of 3D printing started in the 1980’s.

The medical industry has taken this technology on board. 3D printing means that surgeons can make actual mock ups of parts their patients body which needs to be operated on. The doctor just needs to create a design which will then be printed out into a 3D model. Another industry that is now relying on this technology to make their jobs easier is in aerospace. They use this technology to make almost every element and component. 3D printing is used for jewellery, architecture, fashion, art and interior design.

Many different platforms are now able to use 3D printing. The design programs continue to become easier to about master, however many consumers still complain about the design software. The main differences between 3D printing technologies are how the layers are built to create parts. SLS (selective laser sintering), FDM (fused depostion modeling) & SLA (stereolithograhpy) are the most widely used technologies for 3D printing. Selective laser sintering (SLS) and fused deposition modelling (FDM) use melting or softening material to produce the layers.

The demand for 3D printing continues to increase. Some of the market has formed inflated or rather unrealistic expectations. Consumers have therefore been dissatisfied with the appearance and reliability of the 3D printed objects and the design software has been labelled complicated and challenging to master. However 3D printing is still being used by specialists for prototyping. Whether 3D printing will be something eventually used in everyday life such as business card designs

or poster print remains to be seen. The technology is nowhere near perfect but progresses every day. This technology is very useful in many industries, as the prices decrease and technology improves their popularity continues to grow.

Written by Jasmine Poole