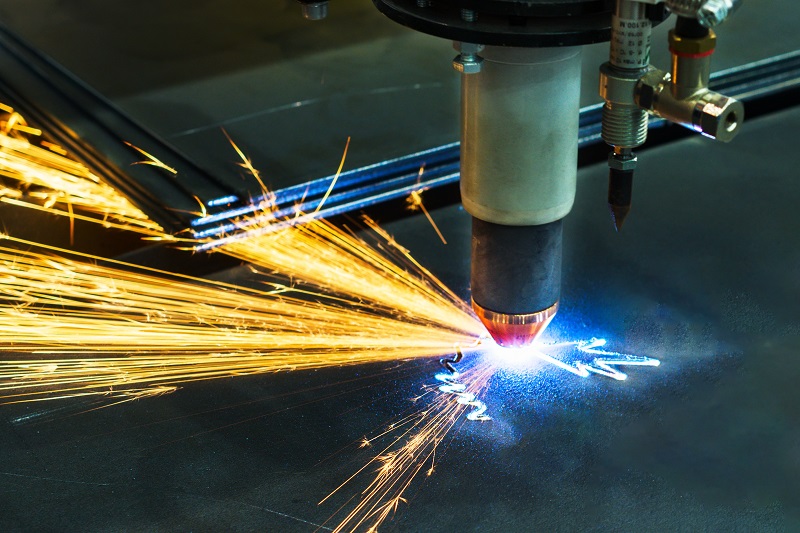

Plasma drilling is one of the new types of drilling tech that has been explored recently. This system acts as a perfect substitute for methods that are mostly based on contact. Based on the current trend, modern technologies that include plasma drilling is based on active research. In addition, it is important to note that only a few company’s welcome plasma drilling across the world.

What Is High-energetic Electric Plasma That Is Used for Plasma Drilling

This technology is being developed by experts in applications to take care of issues related to drilling underwater, in creating deep, efficient holes for bore wells, and many more uses.

The Principle of Electric Plasma

The electric arc is a distortion that is caused by the breakdown of gasses and produces a continuous discharge of plasma. This arc has a lower voltage when compared to a glow discharge and it relies on the thermal emission of a wide variety of electrons emitted from electrodes that support the arc. The factors that influence an electric arc are the outer and inner magnetic fields, the flow of gas, and the elements in the chamber that usually holds the arc. Typically, the development of a highly sustainable arc needs a lot of sustainable processes to take place inside a chamber, specifically made for discharges.

Working of A Plasma Drill

Air that is compressed is flown through a drill rod that is hollow into the plasma drill, where the air is split into two different streams. One of the streams go to the internal electrode with the help of swirling channel, ensures that discharge is fed adequately and blows the arc forcing it to rotate. This rotation helps in avoiding the premature burning of the electrode.

The other stream lowers the temperature of the electrodes by moving around the fins for cooling. A portion of the other stream flows through the lateral openings located in the sleeve for insulation and into a discharge chamber. The plasma formed goes out through one of the nozzles towards the extreme bottom of the hole for drilling. After the electrodes are cooled, a major portion of the second stream goes out from the openings located on the drill cover and moves along with the debris.

Key Advantages of Plasma Drilling

- Plasma drills allow efficient utilization of energy and material, which in turn, increases the overall efficiency of the drilling process.

- Plasma drills work in such a way that mechanical parts need not be replaced. Just the electrodes need to be replaced to get a sustainable flame.

- The plasma drill is made up of a casing diameter that is always a constant.

- Plasma drilling efficiently transports rocks that are disintegrated.

- Plasma drilling is the most efficient when it is used on hard rocks, like porphyritic, quarterstaves, and granite.

- The drilling rate is proportional to the rating of the plasma drill. Plasma drills containing air-swirl arc stabilization and cooled with air are always capable of creating high drilling rates of 4.5m/hr.

- Coaxial whirl plasma drills have grown in popularity because of introducing hydrocarbon with the plasma. These plasma drills have a very high cut rates.

- The drilling occurs with a low fume and consumes little air.

- It has a narrow HAZ.

Some of the disadvantages of plasma drilling are-

- There is a lot of noise when thicker sections are drilled.

- There are fumes emitted when cutting in air.

- Since electrodes need to be replaced frequently, the cost is high.

So, keep this info handy if you are planning to get a plasma drilling.